D. I. Y. LTD Stirlig engine for beginners from Hudák Gábor Mail: hudakgabor(at)freemail.hu

All measure are in European SI

1 inch = 2.54 cm = 25.4 mm

1cm = 10 mm

You will need the following Items:

-2 piece jar lid [10 cm dameterl

-1 piece of a doctofs rubber glove ora balloon

-some strorger wire or paperclipsl for the shaft]

-2 pice of thin wooden rod [d=3-4 mm]

-2 piece straw [the thick one]

-2 beer can [you have to drink the beer first!)

-1 piece plastic ball pen's outer shell

-10 pieces of pearl

-A little piece of depron or EPS foam

differently thick cartboard

-1 small tin can [the bottom, the lid and the body)

Glue:

silicon, quick dry glue, epoxi

Building:

1 step.

We drill a d=12mm hole in one of the lids, the

border of the hole is approximately 12 mm far

from the side ofthe lid. This will be the top.

Now we fold out the knobs of the lid.

2 step:

We cut outa d=93 mm disc pattern from a thicker

mrtboard. We also cut out a 24x297 mm and a

24x20 mm strip from the cartboard. We draw a line

in the middle of the lorger strip[12 mml,now we

bend the strip around the disc we earlier made and

Que the two ends together with the smaller strip.

3 step:

If it's dry we put the pattern disc in the reel, we set

it on the line and then put the reel in the lid and

Que it to it.

4 step:

If it’s dry we fill up the gap between the lid and the

reel we silicon paste. If the silicon is dry we push down

the pattern to the bottom and we mark its center on

the lid. We stab the center of the lid, the hole has to

be big enough for the shaft to move back and forth,

but not to big!

5 step:

The displacer is a d=87 mm and 12 mm high cylinder.

Depron or EPS foam. We drill its center, fill it up with

epoxi and put the shaft in it, when it’ s almost dry ajust

the shaft to 90 degrees in every angle.

6 step:

We cut out a 15 mm long piece from the pen's shell.

From the tin can's lid we cut out a disc the same

diameter as the pen's, we poke out its center for the

shaft. We glue it to the pen. This will be our bearing.

7 step:

We put the displacer int he cylinder, we pull the

bearing ont he shaft and glue itt o the lid. When it’s

almost dry we check that the displacer can move

smooth, it does not hit the side of the cylinder if

moving.

8 step.

Now we put the displacer permanetly in place, we put

the whole thing ont he second lid's outer surface.

We glue it with quick dry glue to keep in place and

then paste it around with epoxi. This will seal our

cylinder hermetically.

9 step.

When the glue is dry web end the shaft of the

displacer to the shape show non the picture.

10 step:

We cut out from cartboard 5-8 rings with 33 mm outer

and 24 mm inner diameter. We glue them togather until

w eget a 4 mm tall tube.

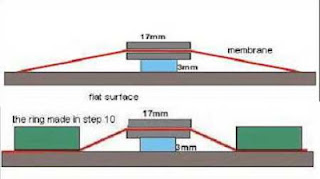

11 step:

We cut out a piece from the rubber glove or ballon, then

we make two d=17mm disc from cartboard, then we glue

them to the opposite sides of the membrane.( be carefull

for the glue should not come out ont he sides because

the membrane may move sidelong)

12 step:

Search for something thats 3 mm tall and fits beneath the

17 mm wide disc and glue itt o it temporeraly. Then put it

down on a flat surface. Then we put some glue on one of

the sides of the ring made in step 10, then push it ont he

mambrane, try to make it concentrical.

Here's some help:

13 step:

We cut off the unecessary rubber then we make a ring

like in step 10 and glue it to the membrane.

14 step:

Put a lot of epoxi on the mambrane mount and glue it on

top of the hole ont he lid. If we worked good then the

mount will not leak. If everything is dry then boil some

water pour it in a glas and put the machine on it. Wait a

little and the start moving the displacer, the membrane

should be moving up and down, if not then there is a leak

somewhere, epoxi everything again.

LTD Building 2.

LTD Building 3.